MEDIN 3D

MEDIN3D - 3D printing pro-tech for personalised fit.

Using cutting-edge scanning, imaging and 3D printing techniques to design and produce prostheses that are tailored to your unique needs. More comfortable, functional and efficient than traditional options.

Tu vas faire des jaloux !

MEDIN3D is a company that was founded in 2016 by three healthcare professionals with the goal of using new technologies to improve orthopaedic equipment for patients and practitioners. MEDIN3D offers innovative solutions for orthopaedic equipment to healthcare facilities and orthotists.

Each year in France, 9,000 people are amputated, with 95% of them from a lower limb. Also, 12,000 to 15,000 prostheses are fitted each year, and many users are in demand for more aesthetic, practical and affordable devices.

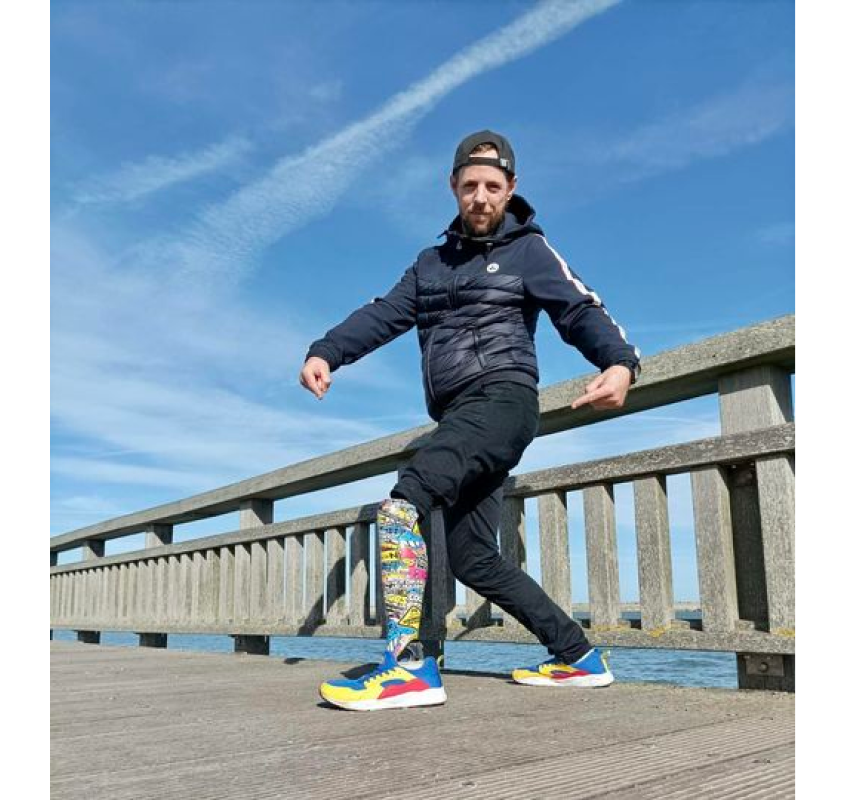

Prosthetic Aesthetics Evolve! The appearance of prosthetics has changed in France over the past decade with new designs being seen in society. While once prosthetics were designed to look flesh-coloured and blend in, now they are decorated and customised. This shift reflects changes in attitudes towards amputation and disability. Media coverage of amputees who display and promote "beautiful" prosthetics has played a big role in this change. Social media has helped spread these images and ideas, leading to a paradigm shift towards valuing and highlighting the prosthesis. The trend of "Body Positive" also aligns with this change. Advancements in materials and tech, like silicone and 3D printing, have also led to the evolution of prosthetic aesthetics.

TIB3D

FEM3D

FANTOM3D

MEDIN3D is revolutionising orthotics. Born from the vision to upgrade orthopaedic devices through tech, MEDIN3D has been offering a 3D-printed products range including the TIB3D© provisional tibial sockets, FEM3D© provisional femoral sockets and FANTOM3D© aesthetic definitive shells, all of which are patented by MEDIN3D. The company became known for its fast manufacturing process using 3D printing with a single data collection sequence, customisation, high-tech finish, ready-to-assemble products, and competitive pricing.

Fantom3D are custom covers made in France for patients, which can be personalised in terms of shape and finish. Each cover is unique, as each patient is unique. Our team has developed a process to improve the daily lives of patients by transforming their prosthesis into an aesthetic accessory that allows them to regain confidence in themselves. The combination of 3D scanning, 3D modelling software, and 3D printing technologies allows us to offer a lightweight and durable product that follows the anatomical curves of the opposite limb for a realistic and unique result for each individual. Whether the patient is tibial, femoral, or bi-amputee, we have a solution that is tailored to each person and offered at an affordable price. The Research & Development department is constantly monitoring new techniques, product concepts, materials and finishes to meet your needs and expectations.

MY ROLE

As a Designer at MEDIN3D, I conducted market and user research to expand the company's product range using existing 3D technologies (3D scan, 3D modelling, 3d Printing). After 8 months of R&D, I presented the first MEDIN3D cover to the team. Testing with beta users confirmed its usability, durability, and desirability.

As Head of Design, I established the 3D modelling process, shared production, found a finishing workshop, participated in website creation, led photo/video shoots, found ambassadors, and continued R&D for updates, new products (sports, activities), new colour ranges and finishings. I helped maintain the brand image through events and online channels. I am so happy to see the brand expanding and users trust, wear and proudly share our work.

How does it work ?

1 - Schedule appointment with your ORTHOTIST

2 -Get 3D SCAN

3 -ORDER on website

4 - magic of 3D MODEL

5 - miracle of 3D PRINT

6 - FINISHING in our workshop

7- SHIP to you

8 - PLUG & CLOSE

9 - GO ENJOY !!!

We wanted to make prostheses and covers a fashion accessory by giving patients the possibility to customize them. To this end, our team worked for six months on the development of a 3D configurator, available for free on medin3d.fr, allowing patients to choose from four ranges of finishes: Paint, Tattoo, Pattern or Customisation.

- The paint range is divided into four families: classic, metallic, chameleon and skin tones, offering more than a hundred references for now.

- The tattoo range currently includes about fifty references, and is always applied to the paint range for the background color.

- The pattern range currently includes 80 references divided into ten categories .

- The custom range offers 100% customisation of Fantom3D.

PAINTS

PATTERNS

TATTOOS

SKIN TONES

We worked really closely with the beauty industry to select and develop 20 skin tones for wide customer coverage.

EFFA

Since 2021 we have started a partnership with the French team of amputee football (EFFA) for their participation in the Euro 2021 in Poland, thanks to the sponsorship of Loger Habitat, by providing covers in the colours of their team.

Excited to see customers proudly posting and tagging MEDIN3D after being in charge of Artistic direction for the company's web presence.